A hydraulic hose is mainly designed to deliver hydraulic fluid to or among hydraulic components, valves, actuators and tools. Since working at excessive pressure, hydraulic hose are frequently strengthened and built with numerous layers at the same time as final flexible. This submit will offer you with the important facts you want to realize approximately hydraulic hoses. This consists of searching on the hydraulic hoses and fittings in addition to the value of buying a hydraulic hose.

How are hydraulic hose made?

The simple hydraulic hose is built of 3 layers. These layers assist preserve a steady and dependable glide of liquid at the same time as protective the hose from breaking down.

Inner Tube: The internal tube is regularly crafted from PDFE, thermoplastic or artificial rubbers. This tube is designed to permit free-flowing elasticity and pressure-resistant bearing at the same time as being like minded with the liquid it carries.

Reinforcement Layer: Comprised of a coil or braided wire. The reinforcement layer surrounds the internal tube, assisting the tubing even as defensive in opposition to tears.

Outer Layer: Made of inflexible materials, this sediment is designed to shield the innards of the hydraulic hose.

How to select the right hydraulic hoses

Temperature

When deciding on a substitute assembly, it’s essential to consider each the ambient temperature and consequently the media temperature. The ambient temperature is that the temperature spherical the hose wherein it’s getting used . The media temperature is that the temperature of the media conveyed via the hose. The hose that’s decided on ought to be equipped to resist the minimal and most temperature of the system.Hoses were given to be equipped to house temperature regions that of the hydraulic fluid which of the surroundings throughout which the hose exists (ambient temperature). Hoses that aren’t designed to stand as much as each the minimal and most temperatures of the fluid, additionally as the ones now no longer designed to discern close to warm manifolds, are probable to fail.Temperature situations of the fluid additionally as in a few instances the floor temperature is moreover vital. The temperature circumstance of the fluid will help you select among our huge selection .All of our hoses are supported application. they’re designed to be ideal for a set of features. that is regularly why we’ve a great range. A hose in particular designed for steam, oil, water, gas, gasoline etc

Size

For a hose to characteristic optimally, its interior diameter need to be huge sufficient to house hydraulic fluid, decrease stress loss and ward off warmness technology or immoderate turbulence, each of which can also additionally harm the hose. in the hydraulics enterprise, the “Dash Numbers” measuring tool is hired to factor hose length and consequently the right accompanying couplings.In order to attend to most reliable characteristic, the inside diameter of the hose need to be huge sufficient to house hydraulic fluid, at the same time as minimising stress loss. This lowers the warm temperature generated through the losses, and decreases the turbulence. a lot of us in the enterprise advise using a Dash Numbers/Dash Sizes dimension to identify the size of the hose fitting. This dimension is that the internal diameter in sixteenths of an in. .The maximum vital detail even as you’re attempting to find your hydraulic hose. the size of the hose play a sincerely vital role.To optimise your process, the internal or interior diameter has were given to be huge sufficient to permit the fluid go through it with out obstruction. If there’s an obstruction in the passage, it’ll reason lack of energy / stress and harm your hose.All different parameters will in large part rely upon the size of the hose, much like the stress rating, quit fittings, flexibility etc.

Pressure rating

This is the maximum crucial component you need to search for within side the hydraulic hose. The stress of the fluid as a way to be exceeded via the hose. It could be very crucial.If you select a hose pipe with a better stress rating, it’s going to now no longer motive tons of a hassle. Your hassle will start if the stress within side the fluid is extra than what the hose can sustain. Every hydraulic hose can have things, operating stress and bursting stress. You can take a look at out our technical specification beneath neath every product and discover those that meet your stress requirements. We usually recommendation which you need to don’t forget operating stress whilst buying your hose pipe due to the fact the existence of utilization relies upon on it. A better operating stress will appreciably lessen the operating existence of your hose.

Compatibility

Generally, alternative hoses must be duplicates of the primary hoses. However, there are situations whilst using a exceptional form of alternative hose is desirable. that is regularly especially true if the hose failed upfront way to immoderate abrasion, uncommon mechanical loads, routing challenges, temperature fluctuation or some other environmental factor. With improvements in hose engineering, there may also be a miles higher hose to be had.As noted previously, a normal hydraulic hose includes a couple of tubes, which includes one inner, one outer and some of different reinforcement layers. Since the hose tube need to are to be had direct touch with the fluid it carries, the tube must be well matched with the gadget’s fluids to carry out reliably. Furthermore, the threads and mechanical interfaces of ends and couplings were given to be well matched with the hoses and different gadget components. If they’re not, leaks and different hose screw ups can occur.

Flexibility

Flexibility method the bends which you genuinely require to your hose to satisfy . This variable is covered altogether technical specs beneath neath the bend radius heading. This metric informs what percentage are you capable of hose bend, in different phrases it’s the pliancy f the hose. The “U” form that’s shaped is measured for this calculation. If you’re doing now no longer have a great deal area and sharp bends, it’s the time wherein you’ll determine in case you would really like to journey in advance with R13 or 4SH, immediately or convoluted. Flexibility can be a crucial element, as all of us recognise that almost all of the time, hydraulic hoses will generally tend to move round with the machines. it’ll input the path and affords the strength of the machines to be flexible.We do apprehend the significance of pliability and the manner critical is it for the hose to preserve the burden and strain at the bends. Therefore, we promote best maximum first-rate merchandise which you’d recognise in case you see the manufacturers we provide . Quality is certainly one of our riding elements and that we don’t compromise

Material

Next, do not forget the situations that a hose will perform under. The outer layer or cowl of a hose can are to be had a variety of rubber materials. Some compositions can assist with packages wherein abrasion might also additionally arise however may not bend as readily. Neoprene is one famous artificial cowl cloth this is nevertheless bendy throughout an awesome variety of temperatures, but handles abrasion properly. Most rubber hoses carry out moderately properly from –40°C (–40°F) to 100°C (212°F). look for the date of manufacture code on any rubber hydraulic hose which you without a doubt are considering. the maximum term is generally ten years on the foremost .

Ends/couplings

Ends of couplings ought to be well matched to their components, to make sure that the relationship is leak-proof. Do now no longer mix ‘n match! It is usually recommended which you select couplings which can be of the identical producer because the hose. Hoses and couplings range among producers, and so blending producers can cause meeting failure. Identify the sort of threads utilized by the system, after which select couplings which can be well suited with the ones varieties of threads. Determine the seat type: thread interface, O-ring, mated perspective or mechanical joint, mated perspective with O-ring. Visually identify, after which degree threads.

Delivery

Determining the amount of fluid that’s attending to go through the hose enables to training session the size of hose which you absolutely were given to use. If you pick a hose that’s too small, it may reason expanded stress loss. Choosing a hose that’s overlarge will reason useless charges and weight.

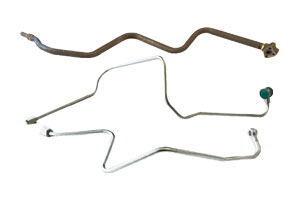

Hydraulic fitting

Hydraulic fittings can join a whole lot of materials, along with tubes, pipes or hoses to additives which include pumps, valves or cylinders. When combining those additives, you create a leak unfastened device that hydraulic fluid permits for secure transmission. There’s a large number of becoming configurations and versions to select from. So, designers have the capacity to alternate the path of flow, break up flows and regulate the elevation of lines. Therefore, we’ve got prepare a few records on a way to select your hydraulic becoming.

Hydraulic coupler

A hydraulic coupling additionally called a fluid coupling is a hydrodynamic tool. The hydraulic coupling is used to transmit whirling mechanical strength. The hydraulic coupling is utilized in vehicle transmissions used as an exchange tool for mechanical clutch. A hydraulic coupling called a hydrodynamic tool may be additionally called a fluid coupling. This hydraulic brief coupling is used to transmit rotating mechanical strength. This hydraulic coupling is utilized in vehicle transmissions and extensively utilized as a mechanical clutch. Also, the use of hydraulic coupling is in marine and commercial device drives as a widespread. Here, the variable pace movement and start-up managed is carried out with out surprise loading of strength transmission system. This utility of hydraulic brief coupling could be very essential.