Fittings are used to make the relationship among sections of pipe with inside the piping gadget. Whether sections have distinctive or identical bore diameter, a specific perspective and plenty more. SS Fittings are maximum favored pipe fittings in piping structures. These fittings are to be had in numerous shapes and dimensions.

SS Fittings aren’t most effective used to attach pipes of various or identical sizes or shapes however extensively utilized for regulating fluid flow. These are the essential a part of piping & tubing structures with out this piping gadget won’t paintings and deliver fluid over small or lengthy distances.

Stainless Steel Pipe fittings are to be had in numerous paperwork like elbow, couplings, union, nipple, reducer, double-tapped bushing, tee, diverter tee, cross, cap, plug, barb, plug, adapter, outlet, lateral tee, and valve.

Stainless Steel

All steels have the same number one iron and carbon composition alongside aspect nickel, but chrome steel moreover consists of chromium – the alloy that gives chrome steel its well-known corrosion resistance.

Austenitic chrome steel consists of immoderate degrees of chromium and nickel and espresso degrees of carbon presenting a balance of strength, workability and corrosion resistance. The latest chrome steel alloys applied in plumbing packages consists of amongst 18-20% chromium and 8-12% nickel, further to small portions of carbon 0.08% and manganese 2%. Austenitic chrome steel has the incredible corrosion resistance and are the maximum usually used type of chrome steel for the duration of the world.

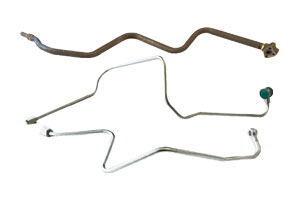

Types of SS Fitting

There are three main types of stainless steel pipe fittings

- Stainless Steel (SS) Buttweld Fittings

- Stainless Steel (SS) Socketweld Fittings

- Stainless Steel (SS) Threaded Fittings

Stainless Steel (SS) Buttweld Fittings

Buttweld pipe fittings contains of prolonged radius elbow, concentric reducer, eccentric reducers and Tees etc. Butt weld stainless-steel and carbon metallic fittings are an essential part of commercial enterprise piping tool to exchange direction, branch off or to mechanically be part of tool to the tool. Buttweld fittings are offered in nominal pipe sizes with unique pipe schedule. BW fitting’s dimensions and tolerances are defined as steady with ASME desired B16.9.

Butt welded Pipe fittings including carbon metal and chrome steel provide many benefits in comparison to threaded and socketweld fittings. The later are simplest to be had as much as 4-inch nominal length while butt weld fittings are to be had in sizes from ½” to 72”. Some of the advantages are weld fittings are;

- Welded connection gives greater strong connection

- Continuous steel shape provides to the energy of the piping device

- Butt-weld fittings with matching pipe schedules, gives seamless float in the pipe. A complete penetration weld and well equipped LR ninety Elbow, Reducer,

- Concentric reducer etc. gives sluggish transition thru welded pipe fitting.

Stainless Steel (SS) Socketweld Fittings

Our SS Socket Weld Fittings Products consist of SS Socket Weld Coupling, SS Socket Weld Half Coupling, SS Socket Weld Cap, SS Socket Weld Cross, SS Socket Weld Tee, SS Socket Weld forty five Degree Elbow, SS Socket Weld ninety Degree Elbow, SS Socket Weld Reducer, SS Socket Weld Reducer Insert and others in good sized variety of sizes, configurations and materials. Stainless Steel Socket Weld Cap is supposed for last and terminating pipe ends, while Stainless Steel Socket Weld Cross is essentially used to provide torque loose and leak loose sealing in any piping or tubing connection.

Stainless Steel (SS) Threaded Fittings

Stainless metal threaded fittings are used to attach metal pipes. Tapered threads are reduce into the quit of the pipe, sealant is carried out with inside the shape of thread-sealing compound or thread seal tape (which is likewise referred to as PTFE or Teflon tape), and a pipe wrench is used to string the pipe right into a threaded fitting. Stainless metal threaded fittings are regularly utilized in homes to bring herbal fueloline or propane fuel, or in plumbing structures. They are a famous desire in hearth place sprinkler structures because of their resistance to mechanical harm and extreme heat.

Benefits of Stainless Steel Fittings

Stainless steel offers a wide range of benefits to the architect and designer of plumbing systems:

Material Benefits

The combining of corrosion resistance with excessive energy permits the discount in wall thickness and weight. Stainless metallic is proof against warmness and chemical damage. It can resist very excessive go with the drift rates – in extra of 40m/s, making it successful to resist long-time period publicity to the factors in nearly any environment.

Environmental Benefits

Stainless metal may be utilized in all styles of water, consisting of consuming water in public supply. It has an high-quality resistance to the overall variety of potable waters, consisting of diverse chloride levels. At the cease of its beneficial life, chrome steel is absolutely recyclable and keeps a better residual scrap fee than regular metal.

Economic Benefits

Stainless metallic is low renovation and calls for no extra coating, in each indoor and out of doors applications. The anticipated life of a stainless-steel machine is greater than 50 years, lowering machine down time, substitute and renovation expenses over the lifestyles of the installation.

SS Fitting Applications

With all of the blessings that include stainless-steel there are similarly simply as many programs in which those fittings may be utilized. Here are a few key useful areas:

- Residential & Commercial water structures which can be challenge to numerous stresses.

- Commercial & Industrial piping structures which can be wanting to carry out properly beneath neath the hardest and most harsh conditions.

- Industrial Projects for sanitary or surprisingly corrosive programs.