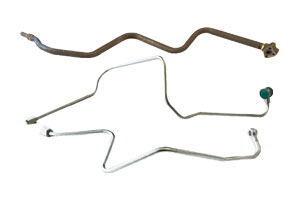

Pipe benders are gear utilized in a technique typically referred to as pipe bending. It is a everlasting technique, consequently an try to repair the pipes to their authentic form can also additionally purpose them to interrupt or harm and decrease their quality. Pipe bending does now no longer require pipe benders, however can assist lots in phrases of ease and convenience. Here’s what it seems like to bend pipes with out the assist of pipe benders.

Pipe benders are gear for bending pipes and tubes fabricated from diverse materials. It can paintings on a number of metals consisting of steel, aluminum and copper after which shape them into diverse curves and angles.

Types Of Pipe Bending

- Compression Bending

- Rotary Draw Bending

- Roll Bending

- Mandrel Tube Bending

- Press Bending

Compression Bending

A compression bending — or press bending as it’s frequently called — is normally composed of the subsequent substances: bend die, clamp die, pressure die, wiper die, and a mandrel. The bend die or tooling issue is the principle component that applies stress at the pipe specimen to mould it. Likewise, the clamp die helps the specimen as its being fabricated in vicinity, at the same time as the wiper die is answerable for stopping defects to take vicinity at the fabric because the method is ongoing. Although the mandrel may be a function of a compression bending machine, it’s some distance extra ubiquitous within side the mandrel tube bending method which you’ll find out later on. Compression is a reasonably easy method to bend pipes. On one aspect a desk bound bend die is constant in vicinity. Compression dies placed on the alternative aspect places sufficient stress closer to the tube to attain the desired attitude or curve. This approach is utilized in making uniform portions with the equal angles on every aspect. It is not unusual place in towel racks, electric conduits, and different creation substances. It is simplest utilized in thick substances to lessen the opportunity of breakage.

Rotary Draw Bending:

Rotary Draw Bending is through a long way the maximum famous shape of tube bending as it’s miles simplest to manipulate, extra unique,repeatable and a pretty inexpensive tube bending device. A Rotary Draw Bending device is made up of 3 special tools, the Clamping Die, the Pressure Die and the Radius Die that preserve and shape the tube during the bending manner. The tube is clamped to the bend die and is ‘drawn’ across the die through the system through both hydraulic or electric powered methods. As the bending die rotates the tubing is held in area firmly towards the rotating bend die through the strain die.

A extra unique kind of bending is rotary draw bending. This kind of bending makes use of a rotary draw system, which bends the steel via a sequence of die units with a regular middle line radius. Rotary draw benders permit for extra particular jobs and are used to bend tube and pipe for merchandise like roll cages, hand rails and handles.

This technique is appropriate for growing extra unique and regular bends. It calls for the use of various dies to finish a smooth and easy product. A clamp die holds a pipe in area even as it’s miles driven through the strain die. What awaits is the bend die that’s wherein the pipe will make its curve or angle.

Rotary Draw Bending is utilized in programs that require an aesthetically captivating product. This manner lets in extra manipulate than press bending, which additionally effects in possibilities for customization.

Roll Bending

Roll bending includes using a device with 3 rollers, known as a jig. It may be used to bend each sheet metallic and metallic bars. It works through setting the bar into the jig and manually decreasing and urgent the center curler towards the bar. As the rollers are rotated, the bar actions alongside and pressure is carried out to the bar because it is going backward and forward alongside the rollers till it reaches the favored shape.

Roll Bending is any other technique of tube bending that makes use of a three or four roll device known as an Angle Roll or Section Roller to tug the tube or pipe thru the rolls whilst urgent the tubing into an growing bend. This technique, just like Press Bending, makes use of a triangular sample of assist rollers and urgent curler, but in contrast to Press Bending this technique can bend a lot of angles utilising the equal form of rollers because the tube or pipe actions thru the bending series through the powered and turning rollers. This technique may be an clean and unique manner to bend a lot of radii with out the want for precise tooling for the favored bend radius favored.

Commonly used for big work pieces in construction, roll bending normally includes 3 rolls located in a pyramid, orientated both vertically or, for large sections, horizontally. The rolls flow to provide precise, commonly very big radii. Which rolls flow wherein relies upon at the device. On some, the pinnacle roll actions up and down to provide the favored angle; on others, the 2 backside rolls flow and the pinnacle roll stays stationary

Another device kind is the 2-roll, pinch-fashion roll bender. For this system, the tube feeds among an higher and decrease roll, whilst on both aspect adjustable publications flow to provide the favored bend angle.

Many use roll bending to provide spirals. If a workpiece has a one-diameter pitch and a big radius, the operator can carry the tube after one revolution to provide a non-stop coil. Some applications, which include people with a bigger coil pitch, require a further roll that publications the tube outward because the coil is being formed.

Mandrel Tube Bending

Mandrel Tube Bending is sincerely now now not a separate method from the above, Rotary Draw Bending at all, but as an opportunity an addition to Tube Bending Mandrel it. With the capability to form tighter and exacting radii the Rotary Tube Bender can begin to with out troubles crumble the tubing at some stage in the forming method. By along with an internal support, or mandrel, at some stage in the forming method the tube walls can be held employer from collapsing. With the addition of a mandrel, inserted with inside the tube and controlled through manner of manner of the machine at some stage in the bending method, the tube is saved from collapsing in on itself as it is stretched and customary throughout the bending die. The mandrel is quality slightly smaller then the ID of the tubing being bent and affixed with severa flexible allows on a flexible ball mandrels at its end. These ball mandrels flex with the tube being customary and allow the tube to bend on the identical time as supporting the entire of the diameter of the tube on the identical time because the tube is wiping over the mandrel at some stage in the entire bending method.

Press Bending

The simplest and maximum not unusual place form of tube bending, this technique entails urgent a “bend die” in opposition to the pipe to pressure it to comply to the form of the bend. This isn’t a precision shape of bending, due to the fact there may be a few deformation of the pipe because of a loss of inner aid.

Press bending is the oldest commercial tube bending technique. In this approach, the tube is constant at factors and the ram (or the bend die) is pressured in opposition to the tube to comply to the form of the bend. The outside dimensions of the cylindrical ram deliver the traits of the bend to be enforced to the tube.

Press bending is a brief bending approach for symmetrical components and calls for no lubrication and cleaning. However, it’s far hard to make a smaller diploma of bend the use of this approach. It gives no aid at the tube internally; therefore it’s far susceptible to deformation with inside the inner and outside curvatures. It regularly produces an oval cross-phase, relying at the tube’s wall thickness. This approach of bending is hard to govern and is best used while a regular cross-phase isn’t required.