Stainless steel nipples do now no longer stain, rust or corrode the manner trendy metallic ones do. There are extraordinary grades of chrome steel which has an effect on the quantity of resistance to corrosion and heat. In addition, chrome steel isn’t the same as carbon metallic, decided via way of means of the quantity of chromium within. Commonly utilized in some of extraordinary business applications, nipple fittings are made of a whole lot of extraordinary types. Although nipple fittings may be created from a whole lot of extraordinary materials, the chrome steel nipple is the maximum famous sort of nipple, in large part because of its inherent electricity and durability.

Types of Stainless Steel Nipples

Among the diverse varieties of stainless-steel nipple kinds are the hexagonal nipple, close nipple, reducing nipple, long hex nipple, welding nipple, and hose nipple. Basically, a nipple is genuinely a quick period of pipe proposing male pipe threads positioned at each ends, making it feasible to attach different fittings. Nipple fittings that don’t have a phase of unthreaded or naked pipe among the 2 connecting ends are commonly called going for walks nipples or near nipples. When those varieties of nipples are utilized in a connection, most effective a small quantity of the nipple is visible.

Hexagonal Nipple

The Hexagonal nipple usually has male threading on every ends of a hexagonal bolt shape with-inside the center. This allows for clean torquing, tightening, or Hex nipple loosening the use of a wrench. Hex nipples are to be had reachable in some unspecified time in the future of packages that require you to attach brass or steel pipes, every with girl ends. Common packages comprise automotive, plumbing, or industrial.

Close Nipples

The use of a close nipple permits you to create a closed, tight connection among woman threaded metal pipes or fittings. However, there’s a disadvantage to closed nipples. The simplest manner to tighten or loosen a closed nipple is to grip the threaded element with a wrench. Because of this, it turns into smooth for the applicator to harm the threading, requiring alternative of the nipple. Damaged threading can purpose problems together along with your connection if now no longer addressed. These problems can also additionally encompass leaking air, water, or different fluids relying on what software the nipple is getting used for. There are unique gear to be had to help of their use.

Reducing Nipple

For ping systems which require a ex trade in pipe dimension, “decreasing nipple” or “unequal nipple” is used. Reducing nipple takes a woman turning into with a larger connection and attaches it to a smaller one. Care need to be taken at the same time as the usage of the ones additives due to the fact a reduction in pipe diameter can mean extra stress and a extra waft fee with-inside the smaller pipe/turning into.

Welding Nipple

For piping structures which require to be linked to welded pipes or fittings, “welding nipple” is used. Welding nipple has a threaded connection on one quit and a regular reduce pipe at the opposite quit. The unthreaded quit of the pipe offers extra floor location for the usage of welding substances to make a more potent connection. One foremost gain of welding nipple is that after the unthreaded quit is linked, connecting pipes or different fittings to the threaded quit will become tons easier.

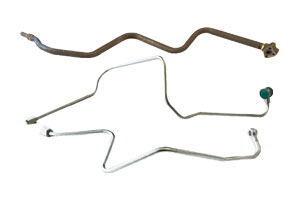

Hose Nipple

For piping structures which require pipe connection to tubing, “hose nipple” is used. Hose nipple abilities a male threaded connection on one surrender and a hose barb at the opportunity surrender. The hose barb may be the equal duration due to the fact the pipe connection or it can be of reduced duration.

Application

Stainless Steel Nipples are first-rate stainless steel fittings which might be high-quality for low-pressure applications in that you need corrosion resistance with-inside the water, oil and the gas. Stainless Steel Fittings have pressure ratings. These ratings are one hundred and fifty psi for water, oil, and gas. Material has a higher corrosion and heat resistance than type 304 material. In addition, all connections are NPT threaded. Custom sizes can be particular ordered. Premium Quality Steel Nipples and Stainless Steel Fittings and Valves are regular and preserve immoderate quality. Popular applications use 304 and 316 Steel Nipples.there are distinctive materials which includes:

- Hydraulic pipe

- Carbon steel pipe

- Aluminum pipe

- Copper pipe

- Brass pipe

- Galvanized pipe